Enhancing Industrial Automation with High Accuracy Electronic Pressure Regulator Technology

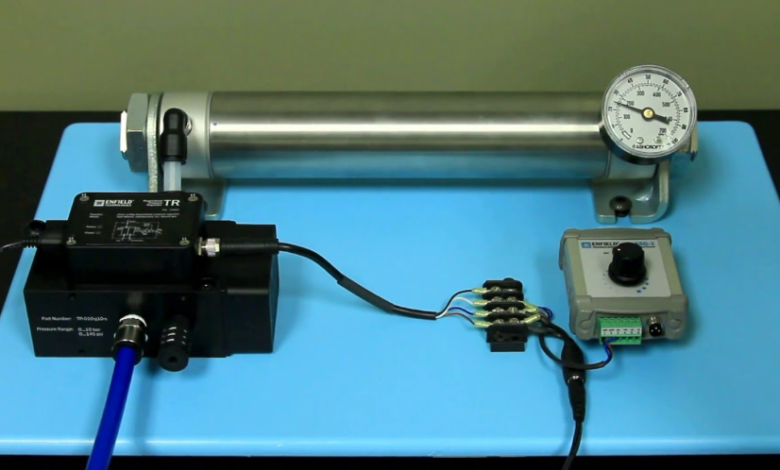

See how an electronic pressure regulator delivers superior precision and reliability in industrial automation with high accuracy. See the function of a proportional pressure regulator, an electronic proportional pressure regulator, and an electro pneumatic regulator system.

Introduction to High Accuracy Electronic Pressure Regulator Systems

In advanced industrial environments of today, precision and efficiency are adequately met by the high accuracy electronic pressure regulator. It ensures the same precise performance of automated systems under varying conditions- be they robotics, manufacturing, or medical systems.

This technology enables seamless pressure control so that waste is minimized while improving operational reliability, integrating a proportional pressure regulator and electro pneumatic regulator system with industrial automation to bring a revolution through real-time electronic pressure adjustment.

See also: A Homeowner’s Guide to Selling a House Quickly in Hawaii

Fundamentals of the Proportional Pressure Regulator

The proportional pressure regulator is considered a device that regulates pneumatic output pressure and an electrical signal in direct proportion. This results in control that is so steady that it makes performance stable.

Main Features

- Converts electronic control signals into accurate pneumatic output.

- Stability of pressure even in varying supply conditions.

- Pressure adjustment repeatability at high-resolution settings.

It runs the proportional pressure regulator right through automated pneumatic systems for seamlessness of transition, plus better accuracy during continuous operations.

Working Principle of Electronic Proportional Pressure Regulator

An electronic proportional pressure regulator controller operates as an interface device between electrical and pneumatic control. It acts by interpreting voltage or current signals into an accurate output air pressure.

- Signal Input: Control input from a programmable system.

- Electronic Conversion: Internally sensed and converted signal.

- Valve Adjustment: Modulation of the valve to set the right output pressure

- Feedback Mechanism: Continuous monitoring and adjustment for accuracy

Such a closed-loop design permits the electronic proportional pressure regulator to preserve great accuracy and responsiveness under highly dynamic industrial conditions.

Advantages of High Accuracy Electronic Pressure Regulator

The high accuracy electronic pressure regulator gives control and flexibility to a degree never seen before in the domain of industrial automation.

Major Advantages

- Accurate Control: Exact pressure value maintained with the least fluctuation.

- Quick to Change: Adjusts at the same speed as the electronic signal is sent.

- Efficient Process: Consumes less air, hence lower energy loss.

- Flexible to Integrate: Works with several systems of control.

- Tough Build: Carries on performing in high-demand operations.

Due to its great exactness and speed, the high accuracy electronic pressure regulator is regularly utilized in robotics, car testing, and semiconductor manufacturing.

Applications of Electronic Pressure Regulator in Automation

At the heart of the precision that automation can achieve is an electronic proportional pressure regulator. It delivers consistent pressure to actuators, valves, and pneumatic cylinders.

Industrial Applications

- Robotic Systems: It supplies stable pneumatic pressure for motion control to be achieved accurately.

- Automotive Testing: Performance can be assessed under constant, maintained pressure.

- Pharmaceutical Production: Controls air flow and pressure in a sterile environment.

- Packaging Equipment: Seal quality depends on it by maintaining consistent pressure.

- Laboratory Devices: Deliver repeatable results in precision testing systems.

It makes the best use of the high accuracy and quickness given by the electronic pressure regulatorr, and controller, therefore improving the total system work.

Integration of Electro Pneumatic Regulator Technology

Electro pneumatic pressure regulators receive digital signals and convert them to mechanical pressure, thereby acting as a link between the electrical and pneumatic control systems.

Advantages of Use

- Ease the joining between the control system and the tools working on pneumatics.

- Gives a well-checked response accompanied by reduced errors.

- Allows quick feedback for closed-loop control.

The application of an electro pneumatic regulator increases system flexibility and lessens manual calibration, suitable for highly developed automation systems.

What Merges the High Accuracy Electronic Pressure Regulator and Proportional Pressure Regulator

Merging the high accuracy electronic pressure regulator with the proportional pressure regulator gives a double benefit: real-time flexibility and steady output.

They boost machine work, cut system lags, and make sure energy use stays at its best. With this mix, industries can get new heights of automation exactness, from assembly paths to space tech uses.

Conclusion

The high accuracy electronic pressure regulators, proportional pressure regulators, electronic proportional pressure regulators, and electro pneumatic regulators are the major precision control devices that have been responding to the evolution of industrial automation.

Stability, accuracy, and responsiveness in demanding environments can be achieved through the implementation of these technologies.

As automation keeps evolving, high-performance pressure control systems are what will be sought to ensure productivity, safety, and quality in all sectors.