Advancements Driving a Modern shanghai pcb assembly factory

Introduction to the Transformation of PCB Assembly

The electronics industry is evolving at an impressive speed, and modern facilities must continuously upgrade their processes to keep up. A shanghai pcb assembly factory is an example of how advanced manufacturing practices can deliver reliable circuit boards for global customers. These factories combine engineering expertise, automated equipment, and strict testing standards to meet the increasing demand for high-quality electronic products.

Why Shanghai Is a Strategic Location for PCB Assembly

Shanghai has become a leading center for electronics manufacturing because of its technological growth, skilled workforce, and efficient infrastructure. Companies select Shanghai-based assembly houses due to their strong track record and ability to offer a balanced combination of innovation, precision, and timely delivery.

Access to a complete supply chain

One of Shanghai’s strongest advantages is the Shanghai PCB Assembly Factory presence of a well-developed supply chain. Component distributors, logistics companies, testing labs, and raw material suppliers are all located nearby, making production smoother and reducing delays.

Engineering talent availability

Shanghai attracts highly trained engineers with skills in PCB layout, design verification, quality inspection, and robotics. This talent pool helps manufacturers solve complex technical challenges and maintain consistent production quality.

High-end manufacturing capabilities

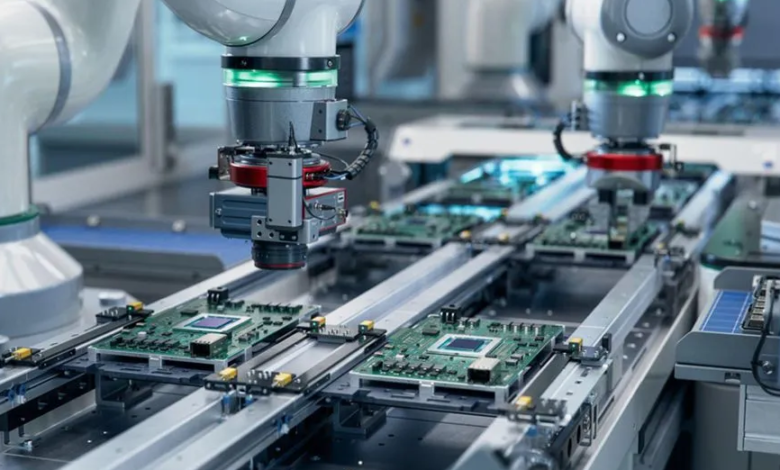

Factories in this region invest heavily in the latest equipment, software, and automation technologies. From smart pick-and-place systems to temperature-controlled soldering ovens, their advanced capabilities allow precise and efficient production.

The Workflow Inside a Professional PCB Assembly Facility

A reliable assembly process requires careful planning and execution. Each step contributes to the quality of the final product, so maintaining consistency across every phase is essential.

Reviewing customer data and files

Before production begins, engineers review design documents, Gerber files, and component lists. This helps identify any potential issues in the layout or component selection. Early detection of design errors can prevent delays and reduce rework.

Incoming components and material checking

A dependable shanghai pcb assembly factory sources components from reputable suppliers to avoid quality issues. Once delivered, each batch of components is inspected for authenticity, specification accuracy, and overall condition. This step ensures that the materials used in production meet industry standards.

Solder paste application

A stencil machine applies solder paste onto specific pads of the PCB. This step must be accurate because inconsistent paste application can cause poor solder joints. Automated printers check alignment in real-time to avoid deviations.

SMT placement and alignment

Surface-mount components are placed using high-speed machines. These machines operate with exceptional precision, ensuring that each component is positioned correctly before soldering. They also handle small components used in dense circuit designs.

Controlled reflow soldering

After placement, the board enters the reflow oven, where solder paste melts and forms permanent joints. Factories maintain a specific temperature profile suited to the board’s material and component requirements. A stable reflow process ensures strong electrical connections.

Through-hole component soldering

If the assembly includes through-hole components, selective soldering or wave soldering machines are used. These technologies create durable joints ideal for parts exposed to heat, vibration, or physical stress.

See also: Brushless Motor Technology: Advancements and Applications

Quality Control Systems Ensuring Reliability

High-quality PCB assemblies rely heavily on strong inspection and testing methods. Shanghai-based facilities invest in multiple quality checkpoints throughout the production line.

Automated optical inspection

A camera-based system checks every component’s orientation, presence, and alignment. It detects common defects such as solder bridges, misplaced parts, and missing components.

X-ray inspection for hidden joints

In cases involving advanced components like BGAs or QFNs, X-ray inspection is used to examine the solder underneath. This technology identifies internal issues that would otherwise remain unnoticed.

Electrical and functional testing

Functional testing ensures the board works properly under real operating conditions. Technicians simulate voltage, signal flows, and other parameters to validate overall performance.

Final visual checks and packaging

Before shipment, each board is inspected by experienced technicians who evaluate craftsmanship, cleanliness, and compliance with customer requirements. Boards are then packaged safely to prevent transportation damage.

Industries That Rely on Professional PCB Assembly in Shanghai

Many industries benefit from the advanced capabilities offered by a shanghai pcb assembly factory. These facilities support both small startup projects and large-scale global product lines.

Telecommunication infrastructure

Modern communication equipment depends on high-quality PCB assemblies for routers, modems, servers, and signal processing units. Shanghai’s manufacturing hubs support this sector with reliable and advanced production systems.

Automotive and electric mobility

Electronic systems in vehicles require high durability and stable performance. Assembly factories in Shanghai produce boards used in battery management systems, sensors, control units, and safety devices.

Healthcare equipment

Medical technology requires precise and dependable electronics. Factories in Shanghai use controlled production methods to meet the strict compliance requirements of the medical sector.

Smart household and consumer devices

From smart speakers to wearable health bands, consumer devices rely on compact and efficient PCB assemblies. Shanghai’s factories offer scalable solutions suitable for both high volumes and prototype batches.

Current Challenges in PCB Assembly Production

Although the industry is highly advanced, manufacturers still face several challenges that demand ongoing development.

Component supply fluctuations

Global supply chain issues can impact component availability. Factories must maintain strategic relationships with suppliers and forecast material needs accurately.

Increasing design complexity

As devices become more compact, the density of components increases. Factories must upgrade their machinery and processes to handle fine-pitch components and multilayer boards.

Strict quality demands

Different industries require boards with varying levels of durability, environmental protection, and reliability. Maintaining consistent quality across thousands of boards is an ongoing challenge.

Rising customization needs

Customer requirements are becoming more specific, requiring personalized production lines and flexible assembly systems.

Technological Trends That Influence Future PCB Assembly

A shanghai pcb assembly factory must adapt to new developments to stay competitive in the global technology market.

Use of artificial intelligence and automation

AI-supported systems help identify potential defects, improve placement accuracy, and optimize production flow. Smart factories are becoming the standard across the industry.

Growth of flexible and wearable technology

Wearable medical devices, bendable phones, and smart clothing require flexible boards. Factories are investing in new machines and materials to support such applications.

Green and sustainable practices

The industry is shifting toward environmentally responsible production. Factories are adopting lead-free solder, recyclable materials, and energy-efficient machinery.

Emphasis on rapid prototyping

With the rise of startups and innovation companies, demand for fast prototype development is growing. Shanghai’s factories support quick-turn production to help businesses accelerate product development.

Conclusion

A shanghai pcb assembly factory represents the modern standards of quality, precision, and innovation seen across the global electronics sector. With advanced automation, strong supply-chain integration, and highly trained engineers, these factories deliver reliable assemblies for a wide range of industries. As technology continues evolving, Shanghai’s role in the manufacturing ecosystem will remain strong, providing efficient and future-ready solutions for businesses worldwide.