The Importance of Skilled Labor in Precision Metal Fabrication

Introduction

In the modern metalworking industry, precision and skill define the quality of production. Among the essential professionals ensuring these standards is the brake press operator. This role is crucial in shaping and forming metal sheets into parts that meet exact engineering specifications. From construction materials to automobile parts and industrial equipment, the accuracy of these components depends heavily on the operator’s technical proficiency and attention to detail.

Understanding the Role

A brake press operator works with a machine designed to bend and shape sheet metal. The operator’s job involves setting up the press, adjusting the dies, aligning the materials, and ensuring the correct bending angles. Each project demands accuracy, as even a small mistake can lead to wasted materials or parts that fail to meet the required tolerances. The role requires both physical and technical skills to handle different metals, machine settings, and safety standards effectively.

Key Responsibilities

The primary responsibility of a brake press operator is to transform flat metal sheets into complex forms according to design blueprints. Operators must interpret drawings, determine the bending sequence, and ensure all parts meet the desired dimensions. They also inspect parts for defects, maintain machine efficiency, and record production data. Regular checks of the press brakes, including hydraulic and electrical components, help prevent breakdowns and maintain consistency in production.

Required Skills and Expertise

Operating a press brake machine demands a blend of hands-on expertise and theoretical understanding. A successful operator must have strong mechanical knowledge and familiarity with various types of sheet metal. Skills such as measuring, blueprint reading, and precision alignment are essential. With many modern presses being CNC-controlled, operators must also be proficient in programming and digital input systems. Problem-solving skills are vital for troubleshooting issues that arise during operation or setup.

See also: The Role of Technology in Building a Sustainable Business

Importance of Training and Certification

Becoming an efficient brake press operator typically requires a combination of formal training and practical experience. Many start through technical schools or apprenticeships that focus on metal fabrication and machine operation. Certifications in manufacturing safety, CNC programming, and blueprint interpretation add value to an operator’s credentials. Continuous education helps professionals keep up with the latest technologies and manufacturing techniques, ensuring they remain competitive in the evolving industrial landscape.

Safety and Precautionary Measures

Safety is a critical aspect of any fabrication job. A brake press operator must always follow standard safety protocols to prevent workplace injuries. Wearing protective gear such as gloves, safety glasses, and steel-toed boots is mandatory. Operators must also ensure that safety guards and light curtains are functioning before use. Regular maintenance and machine inspections further reduce the risk of accidents. Training in safe handling procedures and emergency stops ensures both the operator’s and the facility’s safety.

Advancements in Technology

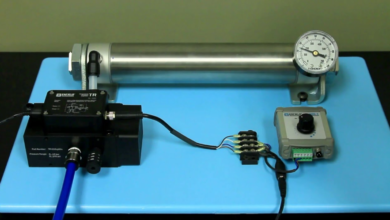

The introduction of CNC and automated press brake systems has revolutionized metal fabrication. Modern technology allows operators to input detailed specifications into a computer interface, ensuring consistent and accurate bends. Although automation reduces manual labor, the skill of the brake press operator remains essential. They must understand how to program, adjust, and maintain these machines brake press operator for optimal performance. The blend of human expertise with machine precision results in higher productivity and improved product quality.

Challenges in the Field

Despite technological progress, the job of a brake press operator comes with challenges. Operators often face tight deadlines, heavy workloads, and complex blueprints requiring high precision. Material inconsistencies, tool wear, and machine malfunctions can also affect quality. Physical strain from handling large sheets of metal and maintaining focus over long hours adds to the difficulty. However, experienced operators develop techniques to manage these challenges efficiently through practice and skill refinement.

Career Growth and Opportunities

A career as a brake press operator offers excellent opportunities for advancement. With experience, professionals can move into supervisory roles, production management, or specialized CNC programming. Those with strong leadership and technical skills may also transition into training or quality assurance positions. The manufacturing industry’s ongoing demand for precision and skilled labor ensures stable employment and room for career growth.

Contribution to Manufacturing Success

The brake press operator plays a central role in ensuring that metal components are formed accurately and consistently. Their ability to interpret technical drawings, operate advanced machinery, and uphold safety standards contributes directly to a company’s productivity and reputation. Every part they shape becomes a component of larger projects—from industrial frameworks to vehicle chassis—making their work an integral part of the production process.

Conclusion

The brake press operator is more than just a machine handler; they are a critical link between technology and craftsmanship. Their knowledge, precision, and commitment to quality ensure the success of every metal fabrication project. As technology advances, the demand for trained and adaptable operators will continue to rise. By mastering both traditional techniques and modern systems, these professionals secure their place in the future of manufacturing and metalworking industries.