Modern Solutions for Precision Metal Bending

Introduction

In the field of metal fabrication, achieving precise bends is crucial for both quality and efficiency. As industries demand higher accuracy and faster production cycles, traditional manual machines often fall short. Modern bending technology has transformed the manufacturing landscape, allowing companies to produce complex components with ease. Among the latest innovations, multi-axis bending systems have become key tools for fabricators seeking both speed and precision.

Advancements in Bending Technology

Historically, metal bending relied on manual press brakes, where skilled operators controlled angles and pressure by hand. While effective for small-scale operations, these machines often introduced variability and required considerable labor. The evolution of hydraulic and CNC-driven machines addressed these challenges, offering automated control, improved accuracy, and repeatable results. The introduction of multi-axis systems further enhanced performance, enabling precise control over multiple parameters simultaneously.

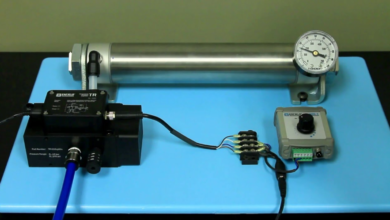

Understanding Multi-Axis Bending Machines

A 4 axis press brake represents a balance between advanced control and operational simplicity. These machines allow operators to independently manage several critical axes during the bending process. This independence ensures that each bend is accurate, even in complex designs, reducing waste and minimizing rework.

Key Features

- Independent Axis Control: Allows precise adjustments for accurate bends.

- CNC Programming: Enables automated sequences and minimizes human error.

- Material Versatility: Can handle a wide range of metals and thicknesses.

- Safety Systems: Integrated guards and sensors protect operators.

- Structural Stability: Heavy-duty frames maintain consistency under high loads.

These capabilities make multi-axis 4 axis press brake machines essential for modern metal fabrication.

Advantages Over Conventional Systems

Compared to traditional single-axis or manually operated press brakes, a multi-axis solution offers several advantages:

- High Precision: Exact angle control ensures uniformity across parts.

- Efficiency: Automated cycles reduce production time.

- Reduced Material Waste: Accurate bends minimize scrap.

- Operator-Friendly: Less dependency on manual skills reduces errors.

- Consistency: Ideal for both small and large production runs.

These benefits are particularly important in industries where precision and reliability are paramount.

Applications Across Industries

Multi-axis bending machines are widely used in various sectors due to their versatility:

- Automotive Industry: Produces brackets, panels, and structural components.

- Aerospace Sector: Fabricates lightweight parts with exact tolerances.

- Construction: Shapes structural elements, enclosures, and decorative panels.

- Electronics: Bends metal panels for devices and housings.

- Custom Fabrication: Perfect for prototypes and small batch production.

The ability to deliver precise bends consistently makes these machines invaluable for diverse manufacturing requirements.

See also: The Role of Tech Platforms in Driving the Next Digital Wave

Enhancing Production Efficiency

A 4 axis press brake allows manufacturers to achieve complex bending operations with minimal effort:

- Back Gauge Control: Ensures precise material placement for consistent bends.

- Tool Alignment: Independent adjustment of multiple axes guarantees accuracy.

- Real-Time Corrections: CNC systems allow adjustments during operations.

- Complex Forming: Multiple bends can be performed without repositioning materials.

These capabilities reduce errors and improve throughput, contributing to a more efficient production line.

Choosing the Right Machine

Selecting an appropriate machine involves evaluating several key factors:

- Number of Axes: Determine the complexity of required bends.

- Drive System: Hydraulic, electric, or hybrid drives offer different advantages.

- Software Interface: User-friendly programming simplifies operations.

- Frame Quality: A stable, robust frame ensures longevity and precision.

- Maintenance Support: Access to reliable service improves uptime.

Proper selection ensures long-term productivity and high-quality output.

Maintenance and Best Practices

Maintaining a multi-axis machine requires a combination of routine checks and operator diligence:

- Regular Inspections: Monitor hydraulic, mechanical, and electrical components.

- Lubrication: Keep moving parts properly maintained to prevent wear.

- Software Updates: Ensure CNC programming is up to date.

- Training: Well-trained operators reduce errors and machine strain.

Following these practices ensures durability, safety, and consistent performance.

Economic Benefits

Investing in modern bending technology provides several financial advantages:

- Lower Material Waste: Precision bending reduces scrap costs.

- Faster Production: Automated sequences increase throughput.

- Reduced Labor Costs: Fewer manual adjustments needed.

- Reliability: High-quality construction minimizes downtime.

These advantages translate to improved profitability and efficiency in manufacturing operations.

Future Trends in Metal Bending

Industry trends indicate continued innovation in bending technology:

- Smart Manufacturing: Integration with IoT for real-time monitoring.

- Predictive Maintenance: Sensors detect potential issues before failure occurs.

- Energy Efficiency: Electric and hybrid systems reduce power consumption.

- Automation: Robotic handling enhances safety and productivity.

These developments are set to further increase the capabilities and efficiency of multi-axis machines.

Conclusion

Modern bending machines, particularly multi-axis systems like the 4 axis press brake, have revolutionized metal fabrication. They offer precision, versatility, and efficiency that traditional machines cannot match. By carefully selecting the right equipment, maintaining it properly, and leveraging advanced features, manufacturers can improve quality, reduce waste, and enhance production speed. As technology continues to evolve, multi-axis machines will remain a cornerstone of advanced metal fabrication processes.