Rapid-response CNC machining helps OEMs reduce costs by 40% and improve delivery efficiency.

Introduction

Original Equipment Manufacturers (OEMs) always face the challenge of high machining costs for parts and the subsequent problem of delivery delays. The main problem has always been the traditional approach to CNC machining services. This approach is always characterized by poor response times and the absence of digital integration. This has been the main reason for the inefficiencies that have been experienced. The solution to these problems is the incorporation of online professional services and rapid response systems that are based on the utilization of high-precision CNC machining. This analysis will seek to explore how this change can be achieved.

Why do OEM Manufacturers Need Rapid Response CNC Machining Services?

In such a competitive space as OEMs, time is an essential factor for controlling market share. According to data from the International Manufacturing Technology Association (IMTS), delays in the supply chain can end up increasing project costs for OEMs by an average of 15%. This highlights the importance of timely delivery for OEMs in OEM parts machining.

The Imperative for Speed in Modern Manufacturing

The traditional method of requesting quotes and starting production can take anywhere from days to weeks. This is no longer acceptable in today’s fast-paced manufacturing world. Delays in receiving vital components can stall production lines, causing costly delays and affecting competitive position.

How Digital Platforms Compress Response Times

Online Professional Services has introduced a solution for this problem with digital platforms that allow for instant upload of design files, instant Design for Manufacturability (DFM) analysis, and instant quoting. This significantly reduces the initial response time from days to just hours. Moreover, it also eliminates the need for costly back-and-forth communication that may end up causing design changes.

Ensuring Reliability in a Fast-Paced Environment

The Role of International Certifications

Speed must not be at the expense of quality. Online machining services from a company with a reputation for quality operate within the guidelines of the International Quality System Standard ISO 9001. This system regulates all steps from the procurement of materials to the end product inspection process.

Standardized Processes for Predictable Outcomes

A company must have standardized processes, as well as a culture of continuous improvement, according to the International Quality System Standard ISO 9001. This ensures that the OEMs get predictable and high-quality outcomes, which is the foundation of a long-term relationship based on trust.

To discover a complete road map to find the right partner, we recommend the OEMs read this comprehensive guide: CNC Machining For OEMs.

How to Select a High-Precision CNC Machining Supplier?

For OEM machined parts, Precision and Accuracy are not up for debate. The process of selecting a supplier involves an in-depth investigation of their quality infrastructure. According to guidelines issued by the American Society of Mechanical Engineers (ASME), it is mandatory for high-precision parts to ensure tolerances as low as ±0.005mm.

To ensure such a high degree of consistency, it becomes essential for a CNC machining parts manufacturer to have a robust quality management system in place.In the case of automotive OEMs, it becomes a requirement for the supplier to be certified to IATF 16949, thus ensuring a high level of commitment towards defect prevention and reduction of variations. The key areas that are taken into consideration while evaluating the supplier are whether the supplier regularly calibrates the equipment, if they are able to implement Statistical Process Control for the real-time monitoring of critical dimensions, and if they have access to sophisticated measurement equipment such as coordinate measuring machines.

Aluminum vs. Titanium: How Does Material Selection Impact OEM Part Costs?

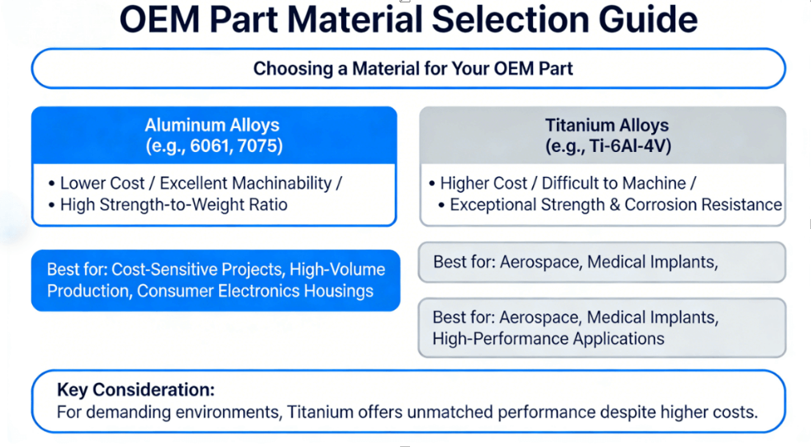

In the case of high volume OEM CNC machining services, the choice of materials is one of the key considerations from the perspective of balancing performance with budget. The traditional debate between aluminum vs titanium for OEM parts has a significant impact on the economics of the end product.

Based on data obtained from different materials databases, such as ASM International, aluminum alloys such as 6061 and 7075 are generally chosen as materials for different structural parts and enclosures due to their high strength-to-weight ratio, good machinability, and excellent thermal conductivity. The cost of aluminum materials is significantly lower than that of titanium materials. In addition, aluminum materials can be machined much faster with less tool wear, resulting in a substantially lower cost per piece. On the other hand, titanium alloys such as Grade 5 exhibit excellent specific strength, corrosion resistance, and biocompatibility.

| Property | Aluminum Alloys | Titanium Alloys |

| Density | Low (~2.7 g/cm³) | Medium (~4.5 g/cm³) |

| Specific Strength | High | Very High |

| Machinability | Excellent | Difficult |

| Raw Material Cost | Low | Very High |

| Typical Applications | Brackets, enclosures, heat sinks | Aerospace components, medical implants |

However, they can be difficult to machine, resulting in a high tool wear rate, hence a substantially higher cost.The cost optimization technique is to adopt composite structures, where titanium is used in high-stress areas, and aluminum is used in other areas. When working in demanding industries such as aerospace, it is important to work with a supplier who is AS9100D qualified to ensure traceability of materials.For expert advice on the selection of materials, Online CNC machining services platforms can be very useful.

See also: Best Travel Destination in 2025: A New Technology of Global Exploration

How is Quality Consistency Guaranteed in High-Volume OEM CNC Machining?

Ensuring that thousands of parts within a high-volume production process have identical Precision and Accuracy is the real test of a manufacturer’s capabilities.This is done through a systematic and automated quality assurance process that goes beyond the capability of human skill.

One of the key methodologies that is used for this purpose is Statistical Process Control. This involves the monitoring and charting of key part features in real-time and adjusting the process prior to any deviation. This ensures that there is no production of parts that are not conforming. Moreover, the use of automated inspection technology also enables the inspection of all key features of every machined part. This is a key requirement in the automotive industry; i.e., every part has to be traceable back to the batch of the material from which it was made and the machine tool that made the part.

Suppliers with implemented Environmental Management Systems such as ISO 14001 have been shown to have more efficient and standardized operations due to their focus on reducing waste and minimizing environmental impact; this indirectly translates to higher quality output.

How Do Online Professional Services Optimize the CNC Machining Process?

Online Professional Services is revolutionizing the OEM machine shops collaboration process through digital tools that enhance integration and transparency. The key is the streamlining of the process.

The Power of Digital Integration

The process begins with a real-time quoting and ordering system. The customer will upload a 3D model, and the system will automatically analyze the geometry, material, and machine time, giving a detailed quote and lead time in minutes. This is an integration of the quoting, ordering, and production scheduling process. Reports have shown that this integration can save up to 30% in communication costs in the supply chain.

The Tangible Benefits of a Rapid Response System

Drastically Reduced Communication Overhead

A Rapid Response System is not just fast quoting; it is a collaborative system. Design engineers and manufacturing experts can provide feedback on the same digital model with the ability to add real-time annotations and comments. This replaces the traditional time-consuming process of sending emails and having meetings to communicate effectively.

Case in Point: Agile Transformation

For example, an integrated online system used by JS Precision helped a consumer electronics original equipment manufacturer transform from final design approval to initiation of machining of the prototype in just 48 hours.

Conclusion

In conclusion, it is evident that the persistent challenges of part cost and delivery speed for original equipment manufacturers can be effectively addressed by embracing digital transformation. This is because an integrated solution of Online Professional Services, Rapid Response Systems, and high-precision CNC machining creates a cohesive solution that will significantly improve efficiency and cost control by streamlining the supply chain, reducing non-value-added time, and ensuring quality consistency.

It is therefore recommended that you consult with a professional service today to obtain a customized CNC machining solution that will optimize your production process and give you a competitive edge in the market.

Author Biography

The company specializes in precision manufacturing services and is certified with various standards such as ISO 9001 and ISO 14001. JS Precision is committed to delivering excellent quality and reliable CNC machining services to global OEMs.

FAQs

Q: How does an online CNC machining service guarantee accuracy?

A: Digital inspection systems and international certification, such as ISO 9001, guarantee an accuracy of ±0.005mm.

Q: What is the minimum order quantity for high volume OEM machining?

A: There is no MOQ as such, although economies of scale are achieved by quantity production. It is usually advantageous to work together from the outset, especially with regard to the creation of a prototype, in order to optimize the process for cost-effective quantity production.

Q: Between aluminum and titanium, which material would you say is better for low-cost OEM parts?

A: Aluminum would be more cost effective, although titanium is used where strength-to-weight ratios or resistance to corrosion are critical.

Q: How can the response time of a CNC supplier be measured?

A: The efficiency of their online system and their case study delivery times are key factors. IATF 16949 is an automotive quality standard that can also be an indicator of an effective management system that is quick to respond.

Q: Can CNC machining be used for parts with intricate shapes?

A: Yes, there is 5-axis technology that can create very intricate parts. It is also important that they have this technology and programming that goes with it.