How Small-Scale Industrial Equipment Manufacturers Can Avoid Costly CNC Material Errors and Achieve 30% Higher Efficiency

Introduction

In the contemporary context of small-scale fabrication of industrial equipment, there is a general problem of costly errors in the material used for the equipment. For example, the choice of the wrong metal alloy may result in the loss of precision and early degradation of the equipment. This is due to the traditional approach to material selection, which is largely based on experience rather than data. There is also the lack of standards for the balance of material properties such as cost and sustainability.

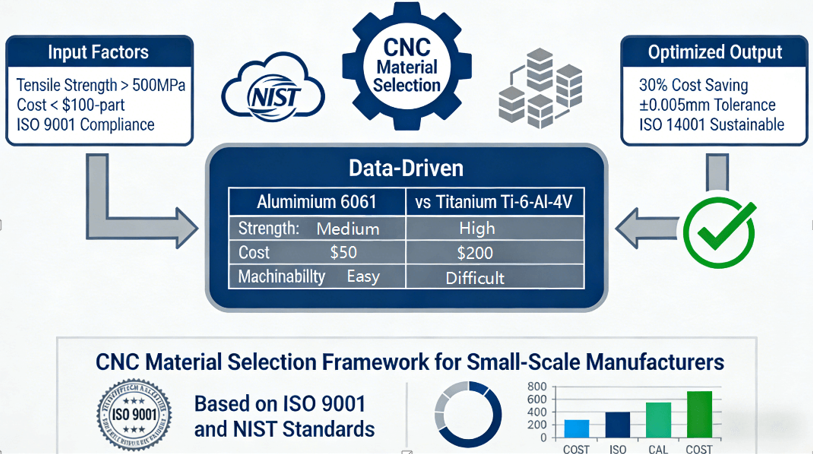

This article is aimed at resolving the problem through the formulation of a data-based approach to the selection of metals for CNC machining that are consistent with standards such as ISO 9001 and the experiences of industry players. This is achieved through an analysis of the questions discussed below to improve the approach for up to 30% efficiency and cost savings.

What Are the Most Common CNC Material Selection Mistakes in Small-Scale Fabrication?

Small-scale fabrication is often characterized by material selection errors due to inadequate analysis and the failure to adhere to standards.

1. Overlooking Material Fatigue Strength and Lifecycle Demands

Quite a few manufacturers place an emphasis on the initial cost or availability of parts and overlook projecting the material long, term durability requirements. As an illustration, drone materials are generally subjected to dynamic forces. Thus, such materials need to have a good fatigue strength to be capable of combating crack formation. Manufacturers referring to ISO 9001 guidelines can confirm the suitability of the materials by imposing certain testing procedures. This will prevent the failure of pieces that may happen if the testing procedures are not performed.If you would like to learn more about the details of machinable metals, please refer to the CNC machining services guide.

2. Neglecting Environmental and Operational Factors

Incidentally, environmental factors play a significant role in determining material performance. Some manufacturers overlook the impact of environmental factors when making their choices. For instance, in the case of medical equipment parts, manufacturers often don’t think about the necessity of corrosion resistance and temperature stability of materials. Instead, they may resort to aluminum alloys, which might not be the right choice. By adhering to ISO 9001 standards, they could examine the materials more closely and ensure that they are indeed the right ones for the intended use.

3. Case Study: Failure Due to Improper Aluminum Alloy Choice

After a small equipment manufacturing company demonstrated the use of sustainable materials e. g. titanium was sourced from recycled aerospace materials, it got the green light for ISO 14001. This move has enabled the company to totally eliminate the waste going to landfill which was their main compliance risk with the environmental regulations. This case is a good example how the certification can serve as a green innovation tool that other manufacturers can replicate to be aligned with the global sustainability trends.

How Can Manufacturers Evaluate Metals for Strength and Cost-Effectiveness in CNC Machining?

The evaluation of metals is a complex process that involves the evaluation of mechanical properties and cost-effectiveness.

1. Key Metrics: Tensile Strength, Hardness, and Cost-Per-Part

Tys are evaluated by measurable parameters such as tensile strength, which refers to the maximum load that a metal can bear. Besides this, hardness is another parameter used to measure the wear resistance of a metal. Comparing aluminum alloys like 6061 to titanium alloys like Ti, 6Al, 4V, we can see that aluminum offers a cheaper route and is easier to machine, whereas titanium in addition to being stronger also comes at a higher price. Besides, cost, per, part calculations help in the selection process by factoring in the costs of machining and wastage. Based on the NIST studies, the evaluation process results in a 25% increase in the efficiency of the manufacturing process by taking into account the smart manufacturing trends.

2. Utilizing Comparative Tables and Certification Benchmarks

Comparative tables are used for putting the characteristics of different materials such as stainless steel and carbon steel side by side. These tables facilitate the selection process by making the differences between the materials more transparent. In addition, certifications like IATF 16949 are being used by the company to guarantee that the evaluation process is being carried out in a standardized manner. Thus, small, scale manufacturers can be helped to achieve the same level of consistency as larger manufacturers.

3. Integrating Real-Time Data and Industry Standards

Advanced practices also include the integration of real-time data from sources such as National Institute of Standards and Technology (NIST) research to monitor the performance of materials under different conditions. This helps make dynamic changes to the selection criteria to match the changing needs of the industry. For example, NIST standards are used to support IoT applications in manufacturing, enabling the application of analytics to predict the behavior of materials. This helps the small shop remain competitive by optimizing the utilization of resources.

What Role Does Precision Play in Selecting Durable Parts for Industrial Equipment?

Precision plays a significant role in the selection of durable parts in CNC machining.

- Tolerance Control and Its Impact on Part Longevity: The control of tolerances such as 0. 005 mm, plays a big role in ensuring the longevity of parts, especially in critical applications like aeronautics or automotive systems. Proper dimensions are necessary to ensure good fit and function, thus lowering the level of stress concentrations. Take the example of turbine parts, even the tiniest deviation may make parts vibrate, thus shortening their lifespan. ISO 9001 is a quality management system standard that encourages precision manufacturing with tight inspection requirements for quality assurance. Small batch manufacturers can resort to advanced CNC machines to realize this.

- Surface Finish and Treatment Techniques: Proper surface treatment like anodizing or coating significantly contributes to the prolongation of the life of the part. For instance, a bad surface that is usually the result of the wrong tool paths or materials, may lead to an accelerated wear of the parts. Studies show that components in the aeronautics sector with the optimized surface finish can endure severe conditions for a longer time, thus saving on replacement costs. By focusing on innovative engineering in surface integrity, companies are thus increasing the lifetime of the parts manufactured.

- Case Example: Aerospace Component Success Through High Precision: With the help of high, precision CNC machining of aluminum brackets, aerospace firms have greatly enhanced the lifespan of their parts. They were able to achieve tolerances as close as 0. 01 mm. This case study is a clear indication of how precision in choosing materials for the purpose of preventing failures matters the most. Local businesses can also attain this level by implementing certified procedures. The illustration is that local businesses are not bound by the lack of achieving quality in processes.

See also: Best Travel Destination in 2025: A New Technology of Global Exploration

How Can Tech Solutions like AI and IoT Optimize Material Selection in CNC Machining?

Various technological breakthroughs have resulted in multiple solutions that significantly make material selection more efficient,and the section will also talk about the role of AI and IoT in the improvement process..

1. AI-Powered Predictive Models for Material Performance

The algorithms used in artificial intelligence systems analyze data patterns to predict how materials will perform under specific conditions, thereby reducing trial and error. For example, machine learning systems can predict material fatigue or thermal expansion characteristics, helping users make optimal decisions for customized projects. Research shows that using artificial intelligence technology can reduce material errors by 30%, which strongly supports the goal of improving efficiency. Companies that comply with the AS9100D standard use these types of tools to ensure compliance.

2. IoT Sensors for Real-Time Monitoring and Adjustment

In CNC machines, IoT sensors recording real, time data on temperature or vibration levels help users gain a thorough insight into how materials interact internally. Based on this information, the rate of feed for brittle materials, for example, may be adjusted. Smart manufacturing through IoT usage is in line with the NIST frameworks; waste reduction is especially focused. Small, scale manufacturers can consider the Internet of Things as a solution.

3. Integrating Digital Twins for Simulation and Optimization

Digital twins, a concept where virtual copies of physical systems are used, simulate material behavior even before the onset of production. Besides, this technology could pinpoint problem areas, like stress points, and suggest alternatives. E. g. , A stress simulation educates one about the strength of different metals. Going tech, manufacturers reduce production expenses and at the same time quicken product creation, which is the case with Industry 4. 0 trends.

What Are the Best Practices for Balancing Cost and Quality in Custom CNC Projects?

Cost and quality balancing is a key to profitability as this section reveals.

1. Adopting Design for Manufacturability (DFM) Principles

Design for manufacturability (DFM) is a methodology for designing products so that they are not only functional but also easy and cheap to manufacture. Moreover, the simpler the product shape, the less material and machining cost involved, for example.Several studies demonstrate that adopting DFM can cut costs by as much as 25% while still maintaining the same level of quality. Consequently, small manufacturers who embrace DFM principles are able to achieve both quality and cost, effectiveness at the same time.

2. Batch Size Optimization and Supply Chain Coordination

Production batches should be optimized for demand to save the cost of storing excess goods. The advantage of small batches is the ability to iterate quickly, whereas large batches leverage economies of scale. Collaborating with the supply chain will set the continuity of material supply and price stabilization.An example of a company saving 30% through efficient planning is a testament to adopting this practice via custom CNC machining service platforms.

3. Leveraging Certification Frameworks for Consistent Quality

Certification frameworks are a great way for companies to keep the quality of their work consistent. In fact, strict adherence to the processes set by such certification frameworks leads to an excellent balance between the cost and the quality of the product. A regular audit can be a great mechanism to detect the inefficiencies that may exist in a company’s operations. A major supplier who implemented the framework was able to cut down their scrap rate by 20%, which shows that being strict really pays off. Local businesses should not rule out the possibility of following the same steps in order to build a good reputation and be competitive.

How Do Environmental Standards such as ISO 14001 Influence Sustainable CNC Material Selection?

Manufacturing revolves more and more around sustainability. The purpose of this part is to show in which ways standards can impact CNC material selection through examples.

- Encouraging Use of Recycled and Eco, Friendly Materials: The ISO 14001 standards offer one avenue to increase the usage of recycled metals and biodegradable materials which can significantly cut down the carbon footprint. For instance, recycled aluminum can save up to 95 percent of the energy used to produce aluminum from virgin ore. Furthermore, this meets the requirements of environmentally conscious customers. Small local businesses can capitalize on such initiatives in improving their brand image.

- Lifecycle Assessment and Waste Reduction Techniques: ISO 14001 mandates lifecycle assessments for evaluating environmental impact starting from extraction up to disposal. Optimizing material usage to minimize waste is part of this and can be done by using nesting software in CNC programming. Research indicates that an improvement of 15% reduction in material waste leads to substantial cost savings. Implementing eco, friendly methods, producers are indeed aiding in achieving the circular economy goals.

- Case Study: ISO 14001 Certification Driving Green Innovation: After a small equipment manufacturing company demonstrated the use of sustainable materials, e. g. titanium was sourced from recycled aerospace materials, it got the green light for ISO 14001. This move helped the company to eliminate the landfill waste which was a compliance risk with environmental regulations. This case illustrates how the certification act as a tool for spurring green innovation which other manufacturers can emulate to be in line with the global sustainability trends.

Conclusion

In sum, this article has presented a detailed discussion on the basic problems of CNC material selection, especially those encountered by small, scale industrial equipment manufacturers. By leveraging data, driven decision, making, precision controls, and technology, such businesses can avoid costly mistakes and can thus potentially improve their operational efficiency by up to 30%. The article mainly focused on mistake avoidance, turning to reliable sources, and environmentally friendly practices for guidance. When one integrates these methods, the process of material selection no longer remains a shot in the dark but rather a competitive advantage.

FAQs

Q1:What metals can be used for CNC machining in order to get high, strength parts?

A: High, strength metals that can be CNC machined are titanium alloys like Ti, 6Al, 4V, which are highly utilized in aerospace technology, and stainless steel, e. g. 304, that is very resistant and has a long service life. One should not only consider tensile strength but also corrosion resistance among other aspects, that is, depend on the project details. Therefore, it is a very good idea to consult the knowledgeable sources if you want a complete guide.

Q2:How much does the choice of material influence the price of CNC machining?

A:How much the choice of material influences the price of CNC machining depends on various factors such as how expensive the materials are, how easy the materials are to machine, and how much waste can be minimized. Choosing an ideal combination of materials can result in a saving of up to 30%..

Q3: What are the minimum certifications that a CNC machining supplier should have?

A:Some of the certifications that you can ask a CNC machining supplier are:Quality management system certification ISO 9001Standard for the automotive industry IATF 16949Standard for the aerospace industry AS9100D

Q4: Are small scale manufacturers capable of the same level of precision as large scale manufacturers?

A:If small, scale manufacturers have the right technology, they can achieve a precision level comparable to big manufacturers (tolerances up to 0. 005 mm). Concerning DFM, it is also a crucial factor..

Q5: How do technology innovations like AI help CNC material selection?

A: AI helps to analyze past data and predict material performance using algorithms, thus helping to avoid trial and error and making the process more efficient with the help of IoT technology.

Author Bio

The author of this article is a manufacturing expert at LS Manufacturing, a company dedicated to helping engineers and researchers solve complex component challenges in the industrial equipment sector. As an ISO 9001, IATF 16949, AS9100D, and ISO 14001 certified team, the company utilizes advanced technologies to ensure high-quality, sustainable solutions. For personalized assistance, contact the team for a free project assessment and detailed material guidelines to help you transform your ideas into cost-eff