Which Laser Machines Are Best for Engraving Tumblers and Cylindrical Items?

Personalized tumblers, cups, and drinkware are some of the best-selling laser products today. From stainless steel tumblers and powder-coated cups to mugs, bottles, and gift drinkware, cylindrical items dominate Etsy shops, craft fairs, and corporate gifting.

At the center of this booming market is one key question:

Which laser engraver for tumblers actually delivers clean, consistent, professional results?

In this in-depth guide, we’ll break down which laser machines are best for engraving tumblers and cylindrical items, what features truly matter, and how different engraving approaches compare. We’ll also explain how Hydra, Hydra Gen 2, X Series, and Vertigo machines fit into real tumbler-engraving workflows—from home businesses to high-volume production.

This article is written for makers, small businesses, and production shops that want reliable, scalable tumbler engraving results.

Why Tumblers and Cylindrical Items Are a Laser Engraving Goldmine

Tumblers are popular because they combine:

- High perceived value

- Strong personalization demand

- Excellent profit margins

- Repeat business potential

Laser engraving adds durability and a premium look that vinyl or printing cannot match.

See also: Best Travel Destination in 2025: A New Technology of Global Exploration

Popular cylindrical products engraved with lasers

- Stainless steel tumblers

- Powder-coated cups

- Travel mugs

- Water bottles

- Glass bottles

- Promotional drinkware

That’s why demand for a laser engraver for tumblers and a laser engraver for cylindrical items continues to grow.

What Makes Tumbler Engraving Different from Flat Engraving?

Engraving cylindrical objects introduces challenges that flat materials don’t have.

Unique challenges of cylindrical engraving

- Keeping the surface evenly aligned

- Preventing image distortion

- Maintaining consistent focus across curves

- Avoiding slippage during engraving

Because of these challenges, not every laser setup works well for tumblers.

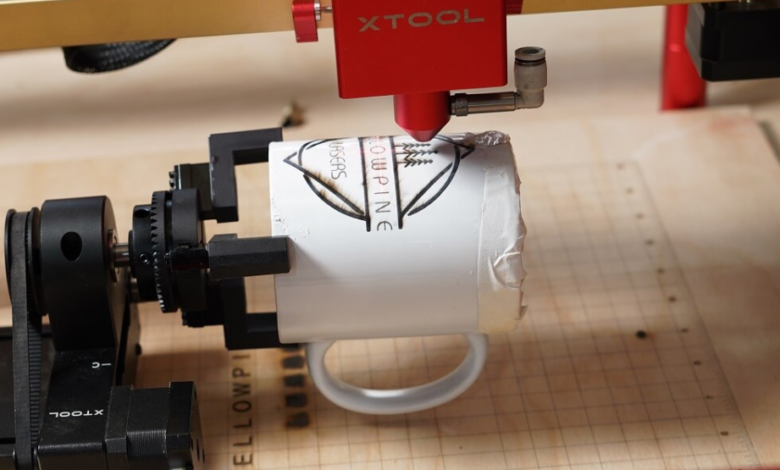

Two Main Ways to Engrave Tumblers with a Laser

There are two primary approaches used in the industry.

1. Rotary Laser Engraving (Traditional Method)

This is the most common approach.

How rotary engraving works

A rotary attachment for laser engraver rotates the tumbler while the laser engraves along the surface.

Advantages

- Works with many flatbed CO₂ lasers

- Flexible for different tumbler sizes

- Widely supported by laser software

Disadvantages

- Requires careful setup and alignment

- Slippage can ruin jobs

- Slower setup for batch production

A rotary laser engraver setup is powerful, but it adds complexity.

2. Vertical / Cylindrical Laser Engraving (Newer Approach)

Instead of rotating the tumbler horizontally, vertical systems engrave with the item standing upright.

Advantages

- Faster setup

- Reduced alignment errors

- Excellent consistency for batch engraving

Disadvantages

- More specialized machine

- Less flexible for non-cylindrical items

This approach is gaining popularity for tumbler-focused businesses.

Best Laser Types for Engraving TumblersCO₂ Lasers for Tumblers

CO₂ lasers are widely used for:

- Powder-coated tumblers

- Painted cups

- Ceramic mugs

- Glass drinkware

They engrave by removing coatings or frosting surfaces.

Pros

- Excellent for coated materials

- Strong contrast

- Affordable and versatile

Cons

- Cannot engrave bare metal directly

- Requires coatings or marking compounds

For many sellers, a laser engraving machine for tumblers using CO₂ technology is the most practical choice.

Fiber Lasers (Brief Note)

Fiber lasers engrave bare metal directly, but:

- They are more expensive

- Not ideal for wood, acrylic, or glass

- Overkill for many tumbler businesses

Most small businesses choose CO₂ solutions instead.

What to Look for in a Laser Engraver for Tumblers

Before choosing a machine, focus on these critical factors.

1. Rotary Compatibility

If you’re using a flatbed laser, rotary support is essential.

Look for:

- Stable rotary attachment for laser engraver

- Adjustable diameter support

- Software integration for rotary mode

A poor rotary setup leads to wasted tumblers.

2. Engraving Consistency

Tumblers require:

- Even engraving depth

- Clean edges

- No stretching or distortion

Machines with stable motion systems and precise control produce better results.

3. Batch Production Capability

Many businesses engrave:

- 10–50 tumblers per order

- 100+ for corporate jobs

Your laser engraver for drinkware must support repeatability and speed.

4. Ease of Setup

Time spent aligning a tumbler is time not engraving.

Simpler workflows mean:

- Higher output

- Less operator fatigue

- Fewer mistakes

5. Space and Scalability

Most tumbler businesses start:

- At home

- In a garage or small shop

Then grow into:

- Dedicated workshops

- Small production spaces

Your laser should grow with you.

OneLaser Machines for Tumbler and Cylindrical Engraving

OneLaser offers several machines that support tumbler engraving at different business stages.

Let’s look at how X Series, Hydra, Hydra Gen 2, and Vertigo fit into tumbler engraving workflows.

OneLaser X Series: Entry-Level Tumbler Engraving

The X Series is a popular starting point for:

- Home businesses

- Etsy sellers

- Craft fair vendors

Why the X Series works for tumblers

- Compact footprint

- CO₂ laser suitable for coated tumblers

- Compatible with rotary attachments

- Easy learning curve

Best use cases

- Powder-coated tumblers

- Small batch engraving

- Personalized gifts

With a rotary attachment, the X Series becomes a reliable laser engraver with rotary for cups and drinkware.

Using the X Series with a Rotary Attachment

With proper setup, the X Series can:

- Engrave logos and text cleanly

- Maintain consistent spacing

- Handle different tumbler sizes

This makes it a strong laser engraver for cups in small-to-medium volumes.

OneLaser Hydra: Production-Ready Tumbler Engraving

As demand grows, many businesses outgrow desktop machines.

The Hydra series is designed for:

- Higher daily output

- Larger work areas

- Faster batch processing

Why Hydra excels at tumbler engraving

- Strong motion stability

- Supports professional rotary systems

- Designed for continuous operation

Hydra is ideal for:

- Corporate orders

- Wholesale tumbler engraving

- Shops engraving tumblers daily

Hydra with Rotary Laser Engraving

Hydra machines paired with a rotary laser engraving machine setup provide:

- Better alignment stability

- Faster engraving cycles

- Reduced vibration

This results in:

- Cleaner engravings

- Fewer rejected tumblers

- Higher profit margins

Hydra Gen 2: Industrial-Grade Consistency

The Hydra Gen 2 builds on the original Hydra platform with improvements focused on production reliability.

Key advantages for tumbler engraving

- Enhanced motion control

- Improved consistency during long runs

- Better thermal stability

For businesses engraving hundreds of tumblers per week, Hydra Gen 2 offers industrial-level dependability.

Vertigo: Purpose-Built Cylindrical Laser Engraving Machine

The Vertigo laser represents a different approach.

Instead of using a rotary, Vertigo engraves vertically, making it a true cylindrical laser engraving machine.

Why Vertigo Is a Game-Changer for Tumblers

Vertigo is designed specifically for:

- Tumblers

- Cups

- Bottles

- Cylindrical drinkware

Key benefits

- No traditional rotary required

- Faster setup

- Excellent repeatability

- Ideal for batch engraving

For businesses focused primarily on tumblers, Vertigo offers one of the most efficient workflows available.

Vertigo vs Rotary Engraving

Feature

Rotary Setup

Vertigo

Setup Time

Moderate to long

Very fast

Alignment

Manual

Automated

Batch Consistency

Good

Excellent

Learning Curve

Moderate

Low

Best For

Mixed products

Tumbler-focused businesses

Vertigo is not a replacement for flatbed lasers—but it is a powerful complement.

Choosing the Best Laser Engraver for Tumblers by Business StageHobby & Startup

Best choice: X Series + rotary

- Affordable

- Flexible

- Easy to learn

Growing Small Business

Best choice: Hydra + rotary

- Faster output

- Better stability

- Professional results

High-Volume Production

Best choice: Hydra Gen 2 or Vertigo

- Maximum consistency

- Optimized workflows

- Reduced setup time

Tumbler-Only Focus

Best choice: Vertigo

- Purpose-built

- Fastest production per unit

Common Mistakes When Choosing a Tumbler Laser❌ Underestimating setup time

Slow alignment kills productivity.

❌ Choosing the wrong laser type

Bare metal vs coated matters.

❌ Ignoring batch consistency

Small errors multiply in large orders.

❌ Buying without a growth plan

Many businesses outgrow their first machine quickly.

Why the Right Laser Increases Tumbler Business Profits

With the right laser engraver for stainless steel tumblers, businesses benefit from:

- Faster order fulfillment

- Lower rejection rates

- Higher perceived value

- More repeat customers

Laser engraving transforms tumblers from simple drinkware into premium products.

Final Thoughts: Which Laser Machines Are Best for Engraving Tumblers and Cylindrical Items?

The best laser engraver for tumblers depends on how you engrave, how much you engrave, and where you want to go next.

- X Series: Best starting point for rotary-based tumbler engraving

- Hydra: Strong mid-range solution for daily production

- Hydra Gen 2: Built for high-volume, continuous engraving

- Vertigo: Purpose-built cylindrical laser engraving machine for tumblers

Whether you use a rotary laser engraver or a vertical system, choosing the right machine ensures cleaner results, faster workflows, and a more profitable tumbler business.

In tumbler engraving, precision and consistency sell—and the right laser makes both effortless.