Choosing the Right Plastic Rebar Chairs for Your Construction Needs

Introduction to Plastic Rebar Chairs

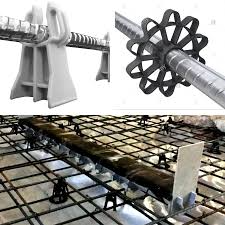

The construction industry has witnessed significant advancements in materials and techniques over the past few decades. Among these innovations, plastic rebar chairs have emerged as a game-changing solution for reinforced concrete construction projects.

These essential components serve as spacers and supports that maintain proper positioning of reinforcement bars during concrete pouring. The transition from traditional metal chairs to plastic alternatives has revolutionized how construction professionals approach reinforcement placement.

Plastic rebar chairs offer numerous advantages over their metal counterparts. They provide excellent corrosion resistance, lightweight handling, and cost-effective solutions for various construction applications. Understanding how to choose the right plastic rebar chairs can significantly impact your project’s success and longevity.

The selection process involves considering multiple factors including load requirements, environmental conditions, and specific project needs. This comprehensive guide will help you navigate through the various options available in today’s market.

Understanding the Role of Rebar Chairs in Construction

Rebar chairs play a crucial role in maintaining the structural integrity of reinforced concrete structures. They ensure that reinforcement bars remain in their intended positions throughout the concrete pouring and curing process.

Proper rebar positioning is essential for achieving the designed structural performance of concrete elements. Without adequate support, reinforcement bars can shift during construction, leading to compromised structural capacity and potential safety issues.

The primary function of these chairs is to maintain the specified concrete cover over the reinforcement. This cover protects the steel from corrosion and ensures proper bond between the concrete and reinforcement bars.

Additionally, rebar chairs help distribute loads evenly across the concrete surface. This distribution prevents point loading that could cause cracking or other structural problems in the finished concrete element.

Modern construction projects demand reliable and efficient solutions. Plastic rebar chairs meet these requirements by providing consistent performance while reducing installation time and labor costs.

Types of Plastic Rebar Chairs Available

The market offers various types of plastic rebar chairs designed for different applications and load requirements. Understanding these variations helps in making informed decisions for specific project needs.

Standard plastic chairs are the most common type, suitable for general construction applications. They come in various heights and are designed to support typical rebar configurations in slabs, walls, and foundations.

Heavy-duty plastic chairs are engineered for projects requiring higher load capacities. These chairs feature reinforced designs and enhanced material properties to handle increased stress and weight.

Adjustable height chairs provide flexibility in achieving precise concrete cover requirements. They allow for height modifications during installation, making them ideal for projects with varying cover specifications.

Specialty chairs are designed for specific applications such as precast elements, curved surfaces, or unusual rebar configurations. These specialized products address unique construction challenges.

Each type offers distinct advantages depending on the project requirements. The key is matching the chair characteristics with the specific demands of your construction application.

See also: Creative Uses for Wire-O Booklets in Everyday Life

Key Factors to Consider When Selecting Plastic Rebar Chairs

Selecting appropriate plastic rebar chairs requires careful consideration of several critical factors. These factors directly impact the performance, durability, and cost-effectiveness of your construction project.

The first consideration is the load capacity requirement. This involves calculating the maximum weight the chairs will need to support, including the weight of reinforcement bars and any additional loads during construction.

Environmental conditions play a significant role in material selection. Factors such as temperature extremes, chemical exposure, and UV radiation can affect the long-term performance of plastic materials.

Project timeline and installation schedule influence the choice of chair type. Some applications may benefit from quick-installation designs, while others might require more robust, permanent solutions.

Budget constraints and cost considerations are always important factors. While plastic chairs generally offer cost advantages, the specific type and quantity needed can vary significantly based on project requirements.

Quality standards and building code compliance ensure that selected chairs meet necessary performance criteria. This includes checking for relevant certifications and approval from local building authorities.

Load Capacity and Weight Requirements

Understanding load capacity requirements is fundamental to selecting appropriate plastic rebar chairs. This involves analyzing both static and dynamic loads that the chairs will experience during construction and service life.

Static loads include the weight of the reinforcement bars themselves. This calculation requires knowing the size, grade, and configuration of the rebar being supported.

Dynamic loads occur during concrete placement and can significantly exceed static loads. These temporary loads must be considered to prevent chair failure during critical construction phases.

Safety factors should be incorporated into load calculations to account for unexpected conditions or variations in construction practices. Industry standards typically recommend specific safety margins for different applications.

Load distribution among multiple chairs affects individual chair requirements. Proper spacing and chair selection help ensure uniform load distribution and prevent overloading of individual supports.

Testing data from manufacturers provides valuable information about actual load capacities under various conditions. This data helps validate theoretical calculations and ensures appropriate chair selection.

Environmental Considerations and Durability

Environmental factors significantly influence the selection and performance of plastic rebar chairs. Understanding these conditions helps ensure long-term durability and structural integrity.

Temperature variations affect plastic material properties. Extreme heat can cause softening or deformation, while extreme cold may lead to brittleness and potential cracking.

Chemical exposure from concrete additives, ground conditions, or industrial environments can degrade plastic materials over time. Selecting chemically resistant plastics is crucial in such applications.

UV radiation exposure, particularly in outdoor applications, can cause degradation of certain plastic formulations. UV-stabilized materials are essential for projects with significant sun exposure.

Moisture conditions influence both immediate and long-term performance. While plastic chairs generally resist moisture better than metal alternatives, proper drainage and ventilation remain important considerations.

Freeze-thaw cycles in cold climates create additional stress on plastic materials. Chairs must be designed to withstand repeated expansion and contraction cycles without failure.

Cost Analysis and Budget Planning

Cost analysis for plastic rebar chairs involves considering both initial purchase costs and long-term value propositions. This comprehensive approach ensures optimal resource allocation for construction projects.

Initial material costs vary significantly based on chair type, quantity, and supplier selection. Bulk purchasing often provides cost advantages, but storage and handling considerations must be factored in.

Installation labor costs differ between plastic and alternative materials. Plastic chairs typically offer easier handling and faster installation, reducing overall labor expenses.

Long-term maintenance costs favor plastic chairs due to their corrosion resistance and durability. Unlike metal chairs, plastic options typically require minimal maintenance throughout their service life.

Potential cost savings from reduced concrete cover requirements can offset higher initial material costs. Some plastic chair designs allow for optimized concrete usage without compromising structural performance.

Total project cost analysis should include potential delays or complications associated with different chair types. Reliable, easy-to-install plastic chairs can contribute to project schedule adherence.

Installation Process and Best Practices

Proper installation of plastic rebar chairs is crucial for achieving optimal performance and structural integrity. Following established best practices ensures reliable results and minimizes potential problems.

Pre-installation planning involves reviewing project specifications, calculating required quantities, and organizing materials for efficient installation. This preparation reduces installation time and prevents delays.

Surface preparation requirements vary depending on the substrate and application. Clean, level surfaces provide the best foundation for chair placement and ensure proper load transfer.

Spacing calculations determine the appropriate distance between chairs to achieve uniform support. This spacing depends on rebar size, configuration, and expected loads during construction.

Installation techniques should follow manufacturer recommendations and industry standards. Proper technique ensures chairs remain securely positioned throughout the concrete placement process.

Quality control checks during installation help identify and correct potential issues before they become significant problems. Regular inspection ensures compliance with project specifications and standards.

Maintenance and Longevity

Maintenance requirements for plastic rebar chairs are generally minimal compared to traditional alternatives. However, understanding proper care practices helps maximize service life and performance.

Routine inspection procedures help identify potential issues before they affect structural performance. Regular visual inspections can detect damage, displacement, or degradation early in the process.

Cleaning requirements are typically minimal for plastic chairs. Occasional removal of debris or buildup helps maintain proper function and prevents potential problems.

Replacement indicators help determine when chairs may need attention or replacement. Signs of excessive wear, cracking, or deformation warrant immediate evaluation.

Preventive maintenance practices can extend service life significantly. These include protecting chairs from unnecessary damage and ensuring proper drainage around installations.

Documentation of maintenance activities provides valuable information for future projects and helps establish realistic service life expectations for different applications.

Common Mistakes to Avoid

Understanding common mistakes in plastic rebar chair selection and installation helps prevent costly problems and ensures project success. Learning from others’ experiences saves time and resources.

Undersizing chairs for load requirements is a frequent error that can lead to failure during construction. Proper load analysis and appropriate safety factors prevent this problem.

Inadequate spacing between chairs can result in uneven support and potential rebar sagging. Following manufacturer recommendations and project specifications ensures proper spacing.

Ignoring environmental factors during selection often leads to premature failure or degradation. Matching material properties to expected conditions is essential for long-term performance.

Poor installation techniques can compromise chair performance regardless of proper selection. Following established procedures and quality control practices ensures reliable installation.

Neglecting manufacturer specifications and industry standards can result in non-compliant installations. Always verify compliance with relevant codes and standards.

Industry Standards and Compliance

Industry standards provide essential guidelines for plastic rebar chair selection, installation, and performance requirements. Compliance with these standards ensures safety and reliability.

Building codes specify minimum requirements for reinforcement support systems. Understanding local code requirements is essential for proper chair selection and project approval.

Quality standards from organizations like ASTM and ACI provide testing criteria and performance benchmarks. These standards help validate product performance and ensure consistent quality.

Certification processes verify that products meet established standards. Look for appropriate certifications when selecting chairs for critical applications.

Professional engineering requirements may specify particular chair types or installation methods. Consulting with structural engineers ensures compliance with design requirements.

Regular updates to standards and codes require staying current with industry developments. Continuing education and professional development help maintain compliance knowledge.

Future Trends in Plastic Rebar Chair Technology

The plastic rebar chair industry continues to evolve with new materials, designs, and manufacturing techniques. Understanding emerging trends helps in making forward-looking decisions.

Advanced polymer formulations offer enhanced performance characteristics including improved strength, durability, and environmental resistance. These developments expand application possibilities.

Sustainable materials and recycling initiatives address environmental concerns while maintaining performance standards. Green building requirements increasingly favor recyclable and sustainable products.

Smart technologies integration may include sensors or indicators that provide real-time information about structural conditions. These innovations could revolutionize construction monitoring.

Manufacturing automation and precision molding techniques improve product consistency and reduce costs. These advances make high-quality plastic chairs more accessible for various applications.

Customization capabilities allow for application-specific designs that optimize performance for particular project requirements. This trend toward specialization improves overall construction efficiency.

Conclusion

Selecting the right plastic rebar chairs for construction projects requires careful consideration of multiple factors including load requirements, environmental conditions, and cost considerations. The advantages of plastic chairs over traditional alternatives make them increasingly popular in modern construction applications.

Proper selection involves understanding the specific demands of each project and matching chair characteristics to those requirements. This process ensures optimal performance while maintaining cost-effectiveness and compliance with industry standards.

The installation process, while generally straightforward, requires attention to detail and adherence to best practices. Quality control throughout installation and periodic maintenance helps ensure long-term performance and structural integrity.

As technology continues to advance, plastic rebar chairs will likely offer even greater benefits through improved materials, design innovations, and manufacturing techniques. Staying informed about these developments helps construction professionals make the best choices for their projects.

The future of reinforced concrete construction will continue to benefit from reliable, cost-effective plastic rebar chair solutions that meet evolving industry demands while maintaining the highest standards of safety and performance.

Certified Material Testing Products (Certified MTP) is a leading supplier of construction materials testing equipment and laboratory supplies in the United States. They offer a comprehensive range of products for testing concrete, asphalt, aggregate, soil, and cement, catering to both field and laboratory applications. However, regardless of whether they are preferred or not, the underlying concept behind these tools is similar: achieving a polished, shiny, and permanent effect. Whether new to stucco or a seasoned pro, investing in quality tools and learning the nuances of their use is what will help you perfect your craft.

Frequently Asked Questions

Q: What are the main advantages of plastic rebar chairs over metal chairs? A: Plastic rebar chairs offer several key advantages including corrosion resistance, lighter weight for easier handling, cost-effectiveness, and no risk of creating electrical paths in the concrete. They also provide better insulation properties and are less likely to cause concrete cracking due to thermal expansion differences.

Q: How do I calculate the load capacity requirements for my project? A: Load capacity calculation involves determining the weight of reinforcement bars, spacing between chairs, and any additional construction loads. Consider both static loads (permanent weight) and dynamic loads (during concrete placement). Include appropriate safety factors and consult manufacturer specifications for actual load ratings.

Q: Can plastic rebar chairs be used in all weather conditions? A: Most high-quality plastic rebar chairs are designed to withstand various weather conditions. However, extreme temperatures may affect performance. Check manufacturer specifications for temperature ranges and consider UV-stabilized materials for outdoor applications with significant sun exposure.

Q: What is the typical lifespan of plastic rebar chairs? A: The lifespan varies depending on environmental conditions and material quality, but properly selected plastic rebar chairs typically last 20-50 years or more. They generally outlast metal alternatives due to their corrosion resistance and stability in various environmental conditions.

Q: How do I determine the correct spacing between rebar chairs? A: Spacing depends on rebar size, configuration, and expected loads. Generally, spacing ranges from 3 to 5 feet for typical applications, but always follow project specifications and manufacturer recommendations. Closer spacing may be required for heavier rebar or higher loads.

Q: Are there any building code restrictions on plastic rebar chairs? A: Building codes vary by location, but most modern codes accept plastic rebar chairs when they meet appropriate standards such as ASTM specifications. Always verify local code requirements and ensure selected chairs have proper certifications and approvals.

Q: How do environmental factors affect plastic chair selection? A: Environmental factors including temperature extremes, chemical exposure, UV radiation, and moisture conditions all influence material selection. Choose chairs with appropriate chemical resistance, temperature ratings, and UV stabilization based on your specific project conditions.

Q: What maintenance is required for plastic rebar chairs? A: Plastic rebar chairs require minimal maintenance compared to metal alternatives. Periodic visual inspections to check for damage or displacement are recommended. Remove debris that might affect drainage, and replace chairs showing signs of excessive wear or damage.